ABS Plus | Adjustable-height void formwork system for lightweight fill applications

ABS Plus void formwork is an adjustable-height concrete formwork system made from recycled plastic. The system is also referred to as disposable formwork, void former, permanent formwork, or single-use formwork. It enables the creation of reinforced concrete raised floors up to 300 cm, offering a lightweight, fast, easy, and economical fill for any structure.

To accommodate project-specific heights, the legs are cut to specification at the factory before delivery. Alternatively, standard-length legs can be cut on-site by the customer to fit the exact heights.

Unlike similar systems, the ABS Plus system consists of 2 legs per m2, which, in addition to the advantages listed below, provides additional ease of application and significant cost savings on concrete and steel.

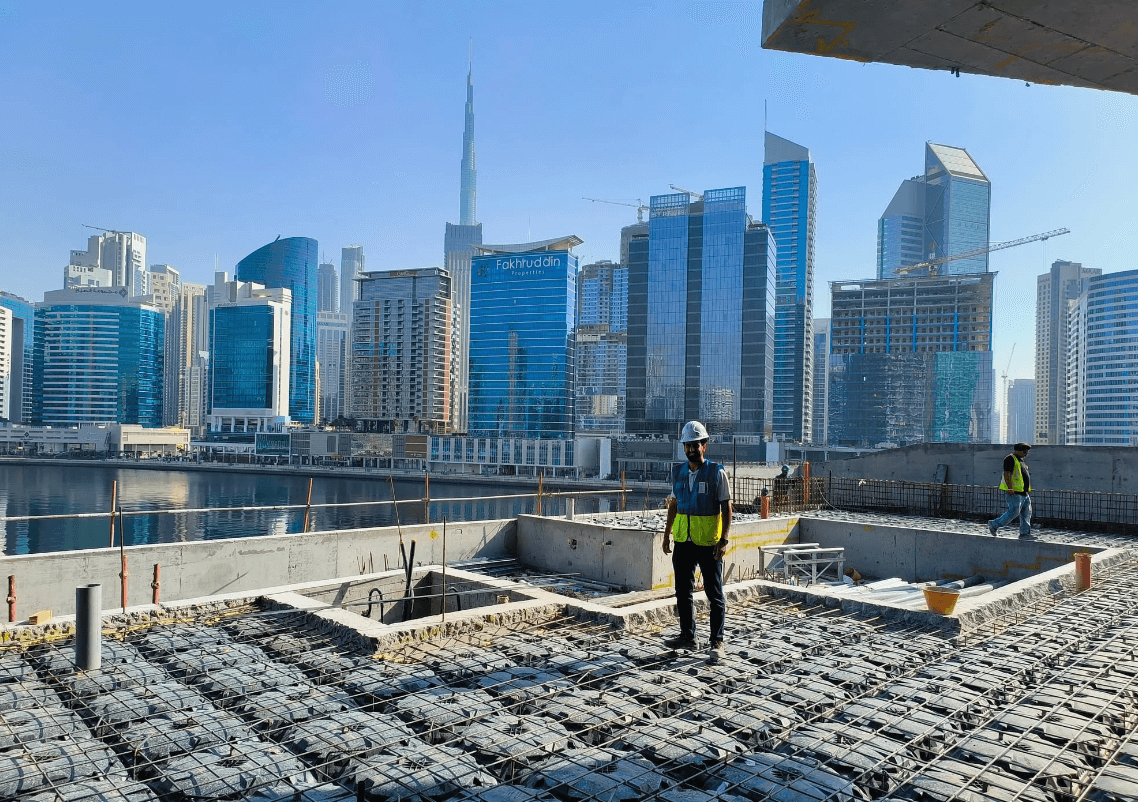

ABS Plus system can be used for various lightweight fill applications. Common uses include sunken slab fills, landscape fills to create hardscape surfaces, amenity floor construction, inverted beam fills, fills between foundation footings, car park ramps, swimming pool decks, elevator/staircase hallway fills, crawlspace construction, low-voltage distribution rooms and rainwater harvesting.

▶︎ The lightest solution to any fill problem: Regardless of the height, only the weight of the topping concrete is added to the structure. In addition, the arch-dome shape of the formwork reduces the required thickness of the topping concrete.

▶︎ Unmatched logistical advantage: The design makes the system components stackable, nesting in each other, providing enormous space efficiency. At a sample height of 100 cm, 1 truck of void formwork equivalents 50 trucks of alternative fill material!

▶︎Very high load bearing capacity: At a sample height of 100 cm with only 5 cm of topping concrete the live load bearing capacity is 55 kN/m2.

▶︎ Reduced construction time: Construction activities on upper floors can proceed without having to wait for the fill application on lower floors, as the fill application can be done anytime, saving very valuable construction time.

▶︎ Void space creation: The void space that gets created under the domes has a net width of 59 cm between Ø125 mm columns. This means that any sort of electrical or mechanical installation can be passed through it either before or after construction.

▶︎ Fast and easy installation: Installation can be as fast as 20 m2/hour and requires no skilled labor.

▶︎ Ramp construction: The legs can be cut at any size needed to create a ramp.

▶︎ Continuous concrete surface: Any sort of covering (epoxy paint, wood flooring, asphalt etc.) can be applied on the concrete surface very easily. Similarly, separator walls can be installed directly on the surface.

▶︎ Heat and sound insulation: The void spaces can provide a degree of heat and sound insulation.

▶︎ Radon gas and damp barrier: If used above foundations and properly ventilated, the system is the most economical and safest way to remove radon gas, humidity and dampness from living quarters.

▶︎ Environmental value: Because the formworks are made of recycled material, they help to gain considerable LEED certificate points.